Steve Garland

-

Increasing The Pace Of Innovation

October 6, 2020

Red Bull Advanced Technologies and BMC prepare to revolutionise cycling performance.

After almost two years of intense research and development, Red Bull Advanced Technologies and innovative Swiss bike brand BMC have moved into the prototyping phase of their technology partnership.

The technical partnership agreement was first signed in 2018, when Red Bull Advanced Technologies, the high-tech performance vehicle solution division of Red Bull Technology, brought its Formula One expertise to bear on BMC’s quest to innovate on the entire cycling experience.

Utilising its advanced simulation and modelling capability Red Bull Advanced Technologies’ Vehicle Science team developed tools to provide detailed simulations of bike behavior based on data from CFD (Computational Fluid Dynamics) models.

BMC is working with Olympic and World Champion, Fabian Cancellara, to validate and evaluate some of the very first hardware developments enabled from the partnership.

Christian Horner, Aston Martin Red Bull Racing Team Principal, said: “It’s been utterly fascinating to see what Formula 1 development techniques can bring to the field of bike design. Together, Red Bull Advanced Technologies and BMC have developed some hugely innovative concepts and now it’s time to step up the pace of our collaboration and take those enormously exciting ideas to the next level in pursuit of the next generation of performance cycling.”

David Zurcher, CEO of BMC, said “We couldn’t be more excited about the progress we’re now seeing, after years of closed-door research. The ideas we’re working on truly have the capacity to significantly improve the entire experience of performance cycling. There’s still work to do, but we’re incredibly energised and motivated by what we’re already seeing. Working alongside the Red Bull Advanced Technology team has been simply phenomenal.”

This ‘transition-to-real-world’ moment is being celebrated with a short teaser video.

General BMC Switzerland -

Gearing Up For The Re-start

June 4, 2020

On Monday, for the first time in 66 days, our Milton Keynes factory opened its doors for F1 work as we begin preparations for a hugely anticipated start of the 2020 Formula One Championship.

The factory shutdown, which forbids any Formula One related activity, was brought forward from its usual August timeframe to March in order to cope with the lockdown resulting from the COVID-19 global health pandemic. However, a little over nine weeks later, we’re gearing up to go racing again, and while we’ve had to implement a range of new procedures to keep everyone safe, the factory is once again a hive of industry, and from design to composites, fabrication to the race bays, work is once again focused on making the RB16 as competitive as possible.

But, while the shutdown meant we couldn’t engage in F1-related activity, it doesn’t mean the factory has been entirely silent over the past two months. As the COVID-19 pandemic worsened, we turned our engineering skill towards a race of a different kind – the one to try and help save lives. Though, in the end, the evolving nature of the crisis and better understanding of the treatment required meant a halt was called to our work, we’re still enormously proud of how we and our partners in the Project Pitlane alliance were able to develop a spark of genius from one junior doctor into an innovative new ventilator device for the NHS in record time.

The brainchild of Dr Alastair Darwood, a member of the NHS England Clinical Entrepreneur Programme, and remarkably, still a Junior Doctor, the BlueSky ventilator is a simple positive pressure ventilator designed for short-term emergency ventilation in trauma and critical care. The UK government identified the ventilator as potentially important in the fight against COVID-19 as it was easily scaleable and had the potential to be mass produced with relative ease, compared to the more complex ventilators already used in critical care settings.

However, despite the cleverness of Dr Darwood’s invention, it was still just a concept and to get the ventilator from concept to production would, in normal circumstances, take a considerable amount of time – a commodity in short supply in a pandemic situation. To change that, Professor Tony Young OBE, Director of Medical Innovation at ARU put Dr Darwood in touch with Innovate UK and in turn with the UK’s F1 teams.

And if there’s one thing F1 teams excel at it’s lightning-quick development and within just two days of the first meeting to analyse the BlueSky ventilator concept at our Milton Keynes factory on 22 March, the first prototype was ready for extensive rig testing leading to the pre-production prototype and ultimate MHRA sign-off.

Our designers and engineers, alongside colleagues at Renault led the charge with mechanical design, manufacturing, electronics and control systems. The Team and Haas also collaborated on mechatronics and mechanical interface, with the other UK teams each playing their part. The Project Pitlane collaboration pooled their extensive network of suppliers within motorsport and the automotive industry including Nissan.

Along with the design task the factories were also re-purposed for mass manufacture of medical grade equipment. Race car assembly bays and composite clean rooms were rapidly re-purposed under the scrutiny of the medical manufacture regulators.

The design and execution of the initial prototype was so impressive that an initial order of units was placed by the UK Government with manufacturing capability being scaled up to provide for 30,000 units if required.

However, as the crisis evolved and the NHS better understood the virus it became clear that enough capacity would exist within the NHS with the existing equipment and the BlueSky project was halted.

Despite the brakes being put on the BlueSky ventilator just days before mass production began, all those involved in the project are hugely proud of the speed at which a clever design became reality thanks to F1’s incredible ability to innovate.

“This project has been an incredible experience and a phenomenal collaboration between many different teams,” said Dr Darwood of BlueSky’s development. “A group of F1 engineers took my initial design and rapidly produced a pre-production prototype capable of mass manufacture and adherence to the rigorous demands of a COVID-19 ventilator. I am deeply honoured to be a part of this process and humbled by the dedication and commitment shown by every member of our team. I’ve seen the engineering skill behind the F1 cars first-hand now; a huge amount of engineering prowess goes into every single element of the car, and their fundamental design skills and problem-solving ability is exceptional.”

And now with, we hope, the worst of the crisis behind us, that engineering prowess can once more be turned towards what we love and do best – building racing cars, making them quick and then quicker again and in the process hopefully bringing back even more silverware to our newly re-opened, race-ready Milton Keynes home.

Project Pitlane -

Formula 1 Statement: Project Pitlane

March 27, 2020

Project Pitlane – Seven UK-based Formula 1 teams making significant progress towards UK Government’s call for assistance with the manufacture of medical devices to help in the treatment of COVID-19 patients.

As confirmed today by The UK Government, during the past two weeks a collective of seven UK-based Formula 1 teams,* their respective technology arms and Formula 1 has made significant progress in defining and coordinating its response to the UK Government’s call for assistance with the manufacture of medical devices to help in the treatment of COVID-19 patients.

The seven teams’ combined efforts, termed ‘Project Pitlane’, are part of a UK industry-wide effort to manufacture and deliver respiratory devices to support the national need.

Following decisions taken this week by the UK Government, Project Pitlane is focussed on three workstreams. These workstreams vary in scope from reverse engineering existing medical devices, to support in scaling the production of existing ventilator designs as part of the VentilatorChallengeUK consortium, to the rapid design and prototype manufacture of a new device for certification and subsequent production.

In each instance, Project Pitlane will pool the resources and capabilities of its member teams to greatest effect, focusing on the core skills of the F1 industry: rapid design, prototype manufacture, test and skilled assembly. F1’s unique ability to rapidly respond to engineering and technological challenges allows the group to add value to the wider engineering industry’s response.

The focus of Project Pitlane will now be on coordinating and answering the clear challenges that have been set. The seven teams remain ready to support in other areas requiring rapid, innovative technology responses to the unique challenges posed by the COVID-19 pandemic.

* Aston Martin Red Bull Racing, BWT Racing Point F1 Team, Haas F1 Team, McLaren F1 Team, Mercedes-AMG Petronas F1 Team, Renault DP World F1 Team, ROKiT Williams Racing

Project Pitlane -

Max and Alex Drive The Valkyrie

February 18, 2020

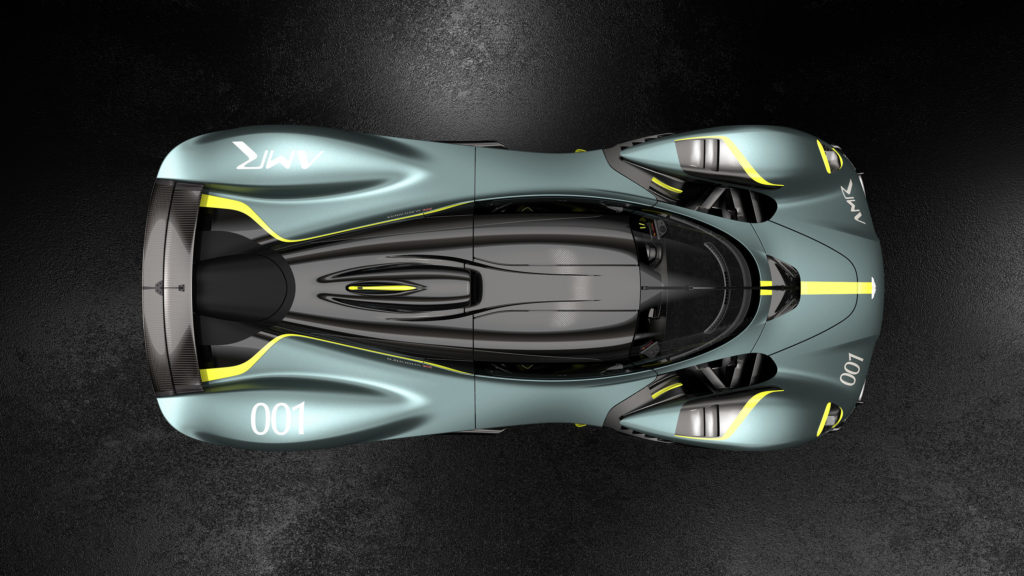

Max Verstappen and Alex Albon got their first taste of the Aston Martin Valkyrie as the Formula One drivers got behind the wheel of the revolutionary hypercar at Silverstone Circuit.

The brainchild of Aston Martin Red Bull Racing Chief Technical Officer Adrian Newey and designed in collaboration with Aston Martin’s Chief Creative Officer Marek Reichman, the 6.5-litre naturally-aspirated V12 Valkyrie aims to bring Formula 1 levels of performance to the road and track.

And with development of the Valkyrie now entering its final phase, Max and Alex were given the opportunity to get behind the wheel of the game-changing hypercar.

As Aston Martin tested a trio of prototypes at the home of the Formula 1 British Grand Prix, Silverstone.

Both Max and Alex opted to test the VP1 prototype in its striking Signature Pack Red Bull-inspired livery, first seen on the Aston Martin Red Bull Racing RB15 and featured on the Valkyrie at its first track test at Silverstone in July 2019.

And Max came away impressed by the Valkyrie’s performance, saying: “I was here at Silverstone to watch the first runs of the Valkyrie at the British Grand Prix last year but of course it’s always better to be behind the wheel yourself.

“To be one of the first guys to drive an insane car like this was really exciting. It was amazing to get a first taste of it,” said Max.

“Of course it’s still in the development phase but you can already feel the pace, which compared to a normal car is… pretty different!” he added.

“The Valkyrie and its levels of downforce are incredible, and it looks super aggressive. It was a lot of fun out there.”

For Alex, today’s Silverstone outing was a first opportunity to see the hypercar in the flesh, and he wasn’t disappointed.

“It was incredibly exciting to have this opportunity and the first thing that struck was the visual aspect – it looks awesome! It also really feels like a racing car,” said the Thai driver.

“Max had a go before me, so the anticipation was building, and to get a chance to drive it was really special and it feels really good.

“Obviously there’s still some development to do, but already it feels very good, especially the balance between the corners. It’s light; it feels sharp.

“Sure, compared to an F1 car, you’re missing the outright downforce, but you still feel the G forces in the corners and it definitely reacts closer to an F1 car than a normal road car.

“It’s pretty special. I just need to get my hands on one!”

The VP1 wasn’t the only Valkyrie on track as the VP2 and VP3 models also took to the circuit at the hands of Aston Martin test drivers Chris Goodwin, Darren Turner and Alex Lynn.

Looking back on the day Alex shared his thoughts on the Valkryie, representing a major achievement for both Red Bull Advanced Technologies and Aston Martin.

“It’s a big achievement for Red Bull Advanced Technologies. Aston Martin have been very welcoming to the idea of a Formula One team working with a car manufacturer, and with Adrian’s help it’s very exciting to take the technology we have at the race track and bring it to the road.”

Aston Martin Valkyrie -

STATEMENT: ASTON MARTIN INNOVATION PARTNERSHIP

January 31, 2020

Following the announcement that Aston Martin’s Title Partnership with Red Bull Racing will conclude at the end of the 2020 Formula One season, Red Bull Advanced Technologies will continue to work with Aston Martin on the Valkyrie project.

Red Bull Advanced Technologies and Aston Martin entered into an Innovation Partnership in 2016 to design the Aston Martin Valkyrie hypercar, which completed its first running demonstration at last year’s British Grand Prix.

The development of the two-seater mid-engine Valkyrie remains a key project for Red Bull Advanced Technologies, with the first batch of the 150 road-going cars due to be delivered to customers at the end of the year.

Aston Martin Valkyrie

-

Flight of the Valkyrie

July 13, 2019

Today Silverstone witnessed the first dynamic running of the Aston Martin Valkyrie.

Piloted by Aston Martin high performance test driver Chris Goodwin, the 1,160 bhp hybrid hypercar, liveried with a stunning Red Bull-inspired design, wowed spectators who, until now, have only officially glimpsed the car on static display.

The run on the world-famous Silverstone circuit represents a design collaboration between Adrian Newey, Aston Martin Red Bull Racing’s Chief Technical Officer, and Marek Reichman, Aston Martin’s Chief Creative Officer, and is the result of a technical partnership between Red Bull Advanced Technologies and Aston Martin.

The initial development phase was completed behind closed doors at Red Bull Advanced Technologies’ Milton Keynes facility, co-located with the Aston Martin Red Bull Racing Formula One Team, and at Aston Martin Lagonda’s global headquarters in Gaydon, Warwickshire. On completion of the lap the Aston Martin Valkyrie leaves Silverstone to begin an extensive physical testing programme before the first of the 150 road-going cars are delivered to customers from Q4 2019.

Chris Goodwin said after the drive, “I’ve driven this car around Silverstone for countless hours on the simulator at Red Bull Racing’s HQ, so to finally drive the Aston Martin Valkyrie here today feels exceptionally special. We still have a lot of development work to do but we can now begin to really push the physical testing process and realise the true capabilities of the car.”

The car is a two-seater mid-engine hypercar, powered by a 6.5 litre naturally-aspirated V12 engine. The 150 road-going Aston Martin Valkyries are already sold out, with the first deliveries commencing in Q4 2019.

Adrian Newey, Chief Technical Officer at Aston Martin Red Bull Racing, said, “To see the Aston Martin Valkyrie running today, five years from the first moment I started sketching what it might look like, is very emotional. With the changing visual angles as it drives past and the noise, it is now doing what it is supposed to do, which is to move and be dynamic. It has been an enormous push from the team to get it running here today so this is also a special moment for them.”

Christian Horner, Team Principal for Aston Martin Red Bull Racing, said, “This first view is the result of a collaboration of design and development between Red Bull Advanced Technologies and Aston Martin. The initial vision was to build a hypercar that would deliver the best in technological advancement and high performance and, together, we have achieved this. This public running is just the beginning of a remarkable story for this car.”

Aston Martin Lagonda President & Group CEO Andy Palmer added, “Today is a milestone in Aston Martin’s history and for our industry as a whole. Aston Martin Valkyrie continues to redefine what you and I recognise as a hypercar, possessing unrivalled levels of performance in a package that is technologically beyond anything else. While Chris’ demonstration today was not delivered at full speed, I’m sure the Valkyrie will return to deliver its full potential around this magnificent circuit in the near future.”

Marek Reichman, Aston Martin Executive Vice President and Chief Creative Officer, said, “We have created a truly unique, beautiful rear mid-engined hypercar in Aston Martin Valkyrie that represents the ultimate fusion of art and technology. I am incredibly proud of everybody at Aston Martin and Red Bull Advanced Technologies to have the Aston Martin Valkyrie run for the first time in public at the British GP.”

As the World Endurance Championship (WEC) is set to begin a new hypercar era in 2020, with new regulations designed to allow race-prepared derivatives of the world’s fastest road cars, the forthcoming Aston Martin Valkyrie race car will draw on all the radical design elements of the road car.

Aston Martin Valkyrie

-

The Full Package?

January 24, 2019

Can you improve on perfect? The Red Bull Advanced Technologies-Aston Martin optional extras suggest you can…

With the Red Bull-Aston Martin Valkyrie moving closer to its delivery date, Aston Martin have announced an options list to add extra-spectacular performance on track, or simply extra spectacular everywhere.

For owners wanting to get their road-going Valkyrie flying on the circuit, the AMR Track Performance Pack delivers a range of benefits designed to drop lap times by around eight per cent. It features a new aerodynamic front clam, delivering greater downforce and efficiency, and a second set of all other exterior body panels.

The pack also comes with lightweight titanium brakes, track-focused suspension, a matte black magnesium performance wheel and carbon-fibre aero-disc set.

Customers also have the opportunity to include a suite of personalised pit garage and race suit accessory options to their package – for that ultimate track day and hypercar ownership experience.

Unlike the track-only Valkyrie AMR-Pro specification, a standard Valkyrie can easily be swapped from road to circuit-spec with the Track Performance Pack, which has been designed to be completely interchangeable with the road-legal components it replaces.

Those not planning to take their absolutely-irreplaceable Valkyrie anywhere near an Armco barrier may still add something more to the package, with a range of four Designer Specification themes available, featuring the exclusive Valkyrie colours Slipstream Green, Liquid Petroleum, Ethanol Silver and Maximum Orange.

Beyond this is an Ultimate Personalisation programme, which invites owners to work with the design team to refine their own specification, including personalisation options and exotic materials from the ‘Q by Aston Martin’ range.

The hybrid Valkyrie is a collaborative project designed under the leadership of Adrian Newey by Red Bull Advanced Technologies and Aston Martin.

Created as a genre-defining road-legal hypercar, it exists at the extreme edge of the performance envelope. 150 road-going and 25 track-only units will be built, with delivery to customers scheduled to begin this year.

Alinghi Red Bull Racing

-

At the heartbeat of the Valkyrie

December 14, 2018

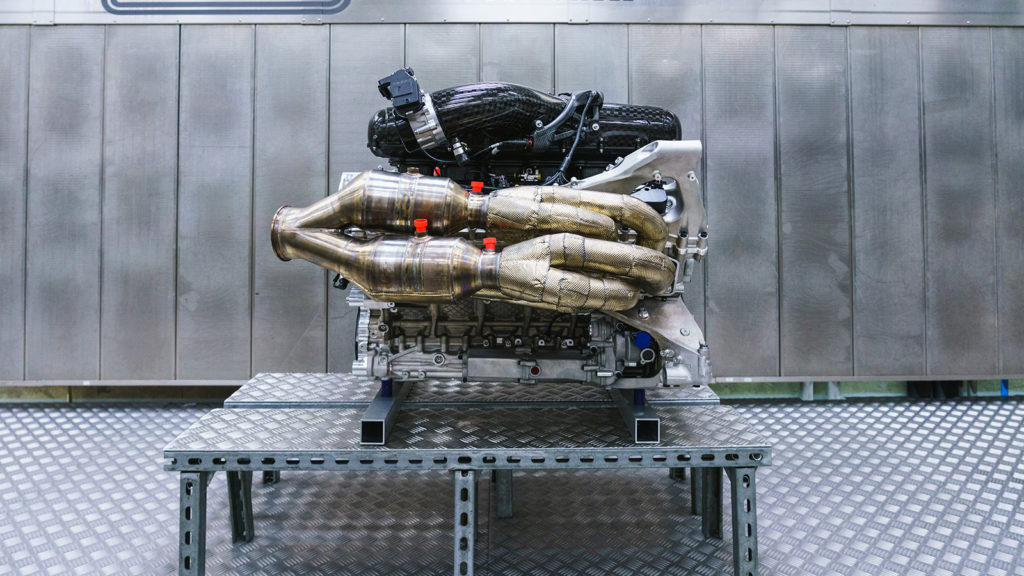

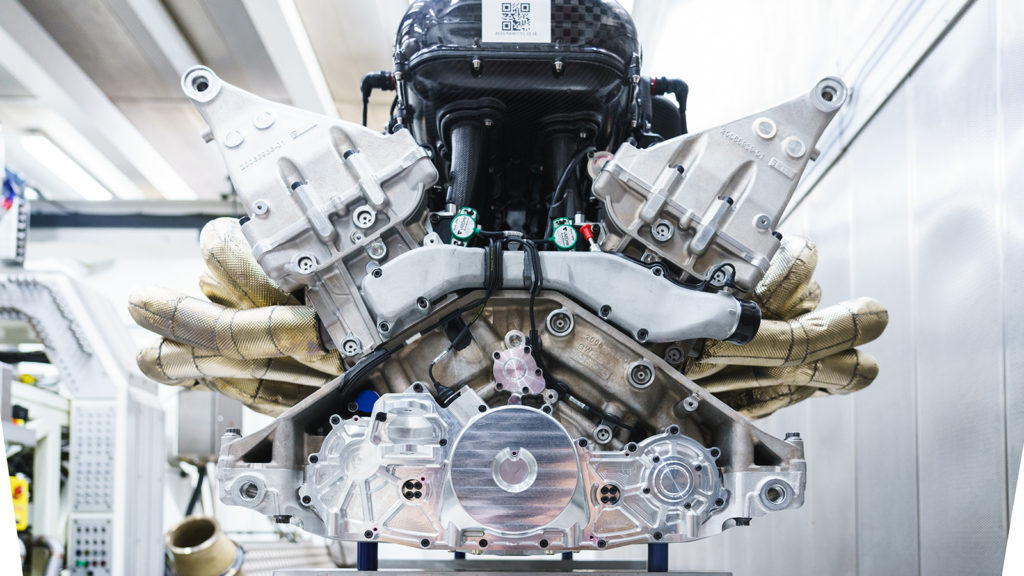

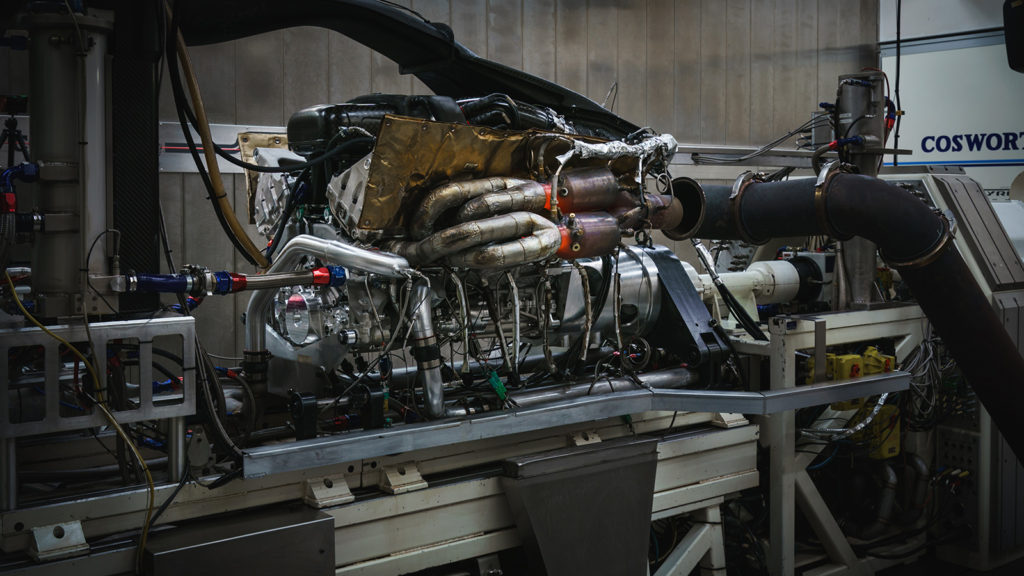

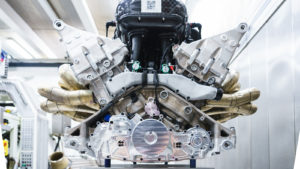

With the delivery date of the first Aston Martin AM-RB 001 Valkyrie drawing ever closer, Aston Martin this week released performance figures for its mighty Cosworth V12 engine.

Like everything else to do with the Adrian Newey-designed hypercar, they exceed a design specification that was truly spectacular in the first place.

As intended from the outset of the project, the 6.5l engine has a certified peak power output of 1000bhp (which works out at an impressive 153.8 bhp-per-litre) reached at a 10,500rpm, before going on to hit the red line at 11,000 rpm.

Thanks to sophisticated materials, technology and advanced production processes, the engine weighs just 206kg and – with shades of F1 – is a fully-stressed element of the chassis. The engine reaches peak torque of 740Nm at 7,000rpm, though this will be supplemented by a kinetic energy recovery system developed by Rimac, the performance of which will be revealed nearer the delivery date.

While the 65° V12 layout harks back to the Formula One we knew in the early 1990s, the addition of a KERS places it firmly in the hybrid era and ensures it meets all programme targets for emissions compliance.

Designed as a collaboration between Aston Martin and Red Bull Advanced Technologies, the Valkyrie is intended to be the ultimate road-going hypercar and thus, Cosworth set out to create the ultimate road-going V12 to complement it.

Cosworth Technical Director Bruce Wood, commented: “Being asked to create a naturally aspirated V12 engine fit for what will surely be one of the most iconic cars of all time is an immense source of pride for Cosworth.

“Decades in F1 taught us to expect a pretty demanding specification from someone with Adrian Newey’s unsurpassed track record, but when we started talking about specifics of power, weight, emissions compliance and durability combined with ever harder and sometimes conflicting targets, we knew this would be a challenge like no other.

“It’s been a fantastic partnership between Aston Martin, Red Bull and Cosworth with each party bringing a distinct clarity of vision that has proved essential in delivering an internal combustion engine way beyond anything previously seen in a road car application.”

The Cosworth V12 will be used in both the Aston Martin AM-RB 001 Valkyrie, and the track-only Aston Martin AMR Pro derivative. Deliveries of the 150 road cars and 25 track variants are scheduled to begin next year, with the entire production run long-since sold-out.

Aston Martin Valkyrie -

Advancing the Development Cycle

May 25, 2018

Red Bull Advanced Technologies, the high tech external solutions division of Red Bull Technology, is delighted to announce that it is to collaborate with premium Swiss bike brand BMC Switzerland.

The co-operation between the two performance-led companies will see Red Bull Advanced Technologies bring its track-bred technical capability to bear on bicycles being designed by BMC Switzerland, which since its establishment in 1994 has championed cutting edge design and manufacture of bikes that have been ridden to numerous Tour de France, Team Time Trial and Road World Championship victories.

As such, Red Bull Advanced Technologies will harness the latest developments in race-refined technology, coupled with intelligent Human Performance Analytics, with specific focus on developing integrated electronic technologies to enhance the cycling experience for every bicycle rider. Red Bull Advanced Technologies personnel will also work closely with BMC Switzerland bicycle engineers on future technical solutions.

Christian Horner added: “There are a huge number of parallels between cycling and motor sport, encompassing materials technology, aerodynamics, human performance analytics, as well as increasing use of electric power solutions. This collaboration is an exciting one for Red Bull Advanced Technologies as we believe that together with BMC Switzerland, who is an undoubted pacesetter in the world of cycling, we can deliver some innovative developments in bike technology. It’s a fascinating project that we’re looking forward to working on with BMC Switzerland.”

David Zurcher, CEO of BMC Switzerland, commented: “We are delighted to welcome Red Bull Advanced Technologies to the world of cycling and are very excited to sign a technical collaboration agreement working closely together on future projects. BMC Switzerland’s brand DNA is built on a strong performance and racing heritage. As such, Red Bull Advanced Technologies is a natural partner for us and everyone at BMC is looking forward to starting this powerful relationship.”

BMC Switzerland